Department

Graphic

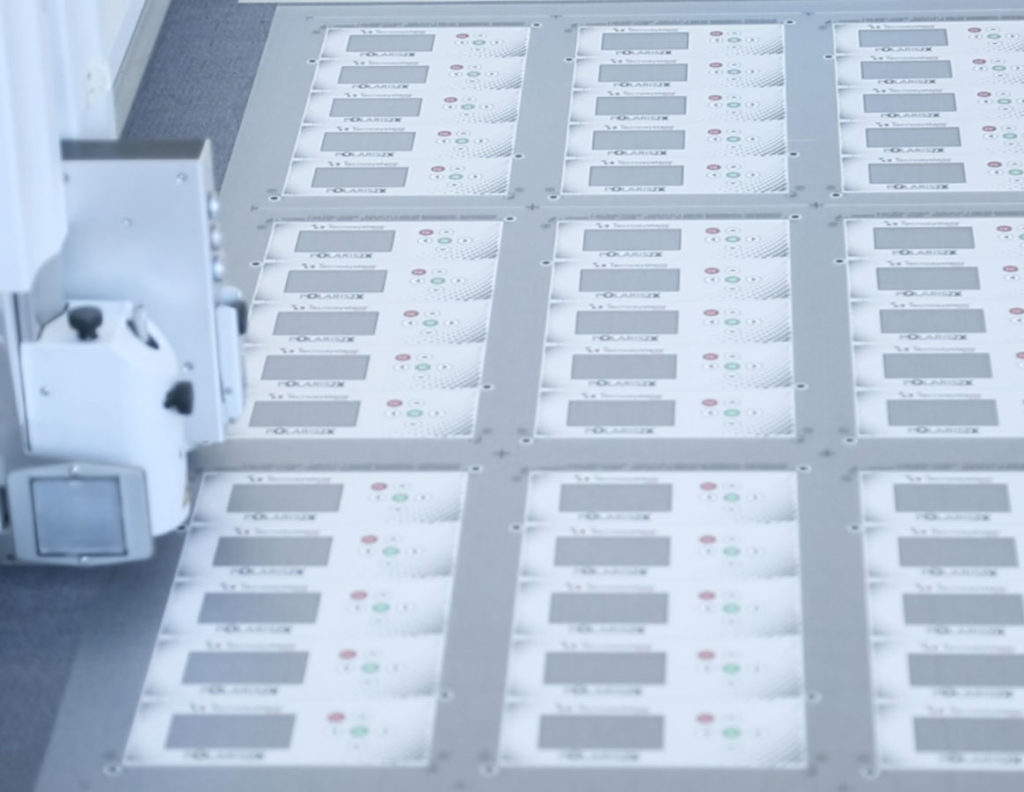

The graphic department designs and creates screens for screen printing processes. It is modern and technologically advanced, equipped with 4 workstations running the latest graphic design software.

The use of tested materials and advanced technologies, the particular attention dedicated to graphic design, and the provision of customer support and collaboration throughout the various stages of the production process, enable us to respond promptly and professionally to market demands.

We are proud to count among our clients leading companies in a wide range of technological sectors: from the electronics industry to consumer products, from household appliances to packaging.

The graphic department designs and creates screens for screen printing processes. It is modern and technologically advanced, equipped with 4 workstations running the latest graphic design software.

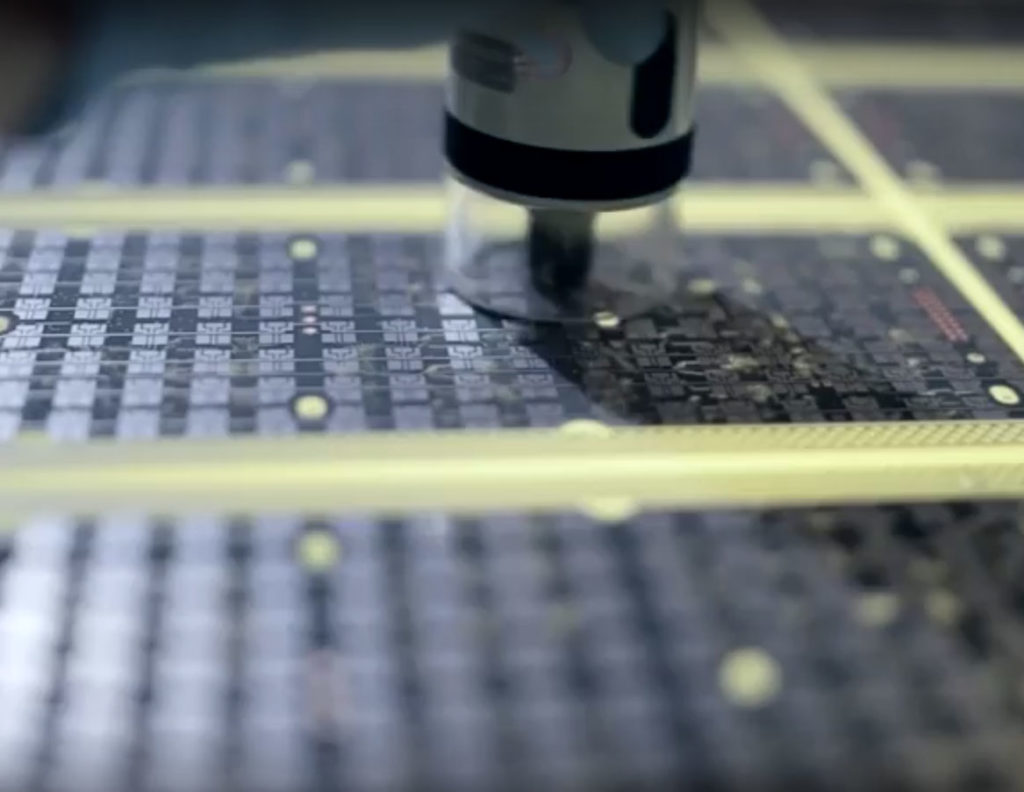

The screen preparation department uses

Il reparto stampa si avvale di macchinari di ultima generazione quali:

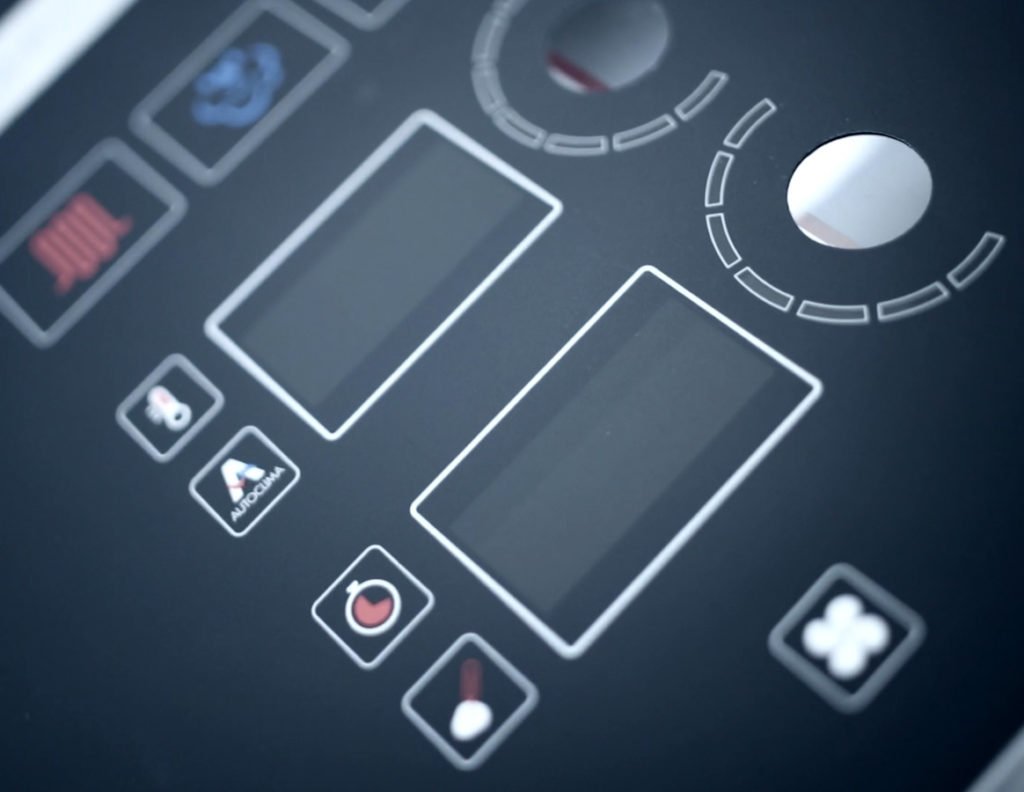

The cutting and punching department is equipped with high-precision machinery such as:

Finally, great attention is given to the quality of the final product, ensured through quality control and testing using:

At Seribell, we manufacture using high-quality materials, guaranteeing their durability.

Optimized production processes, a well-organized quality management system, and particular attention to environmental aspects have enabled Seribell to obtain several certifications.