Graphics

department

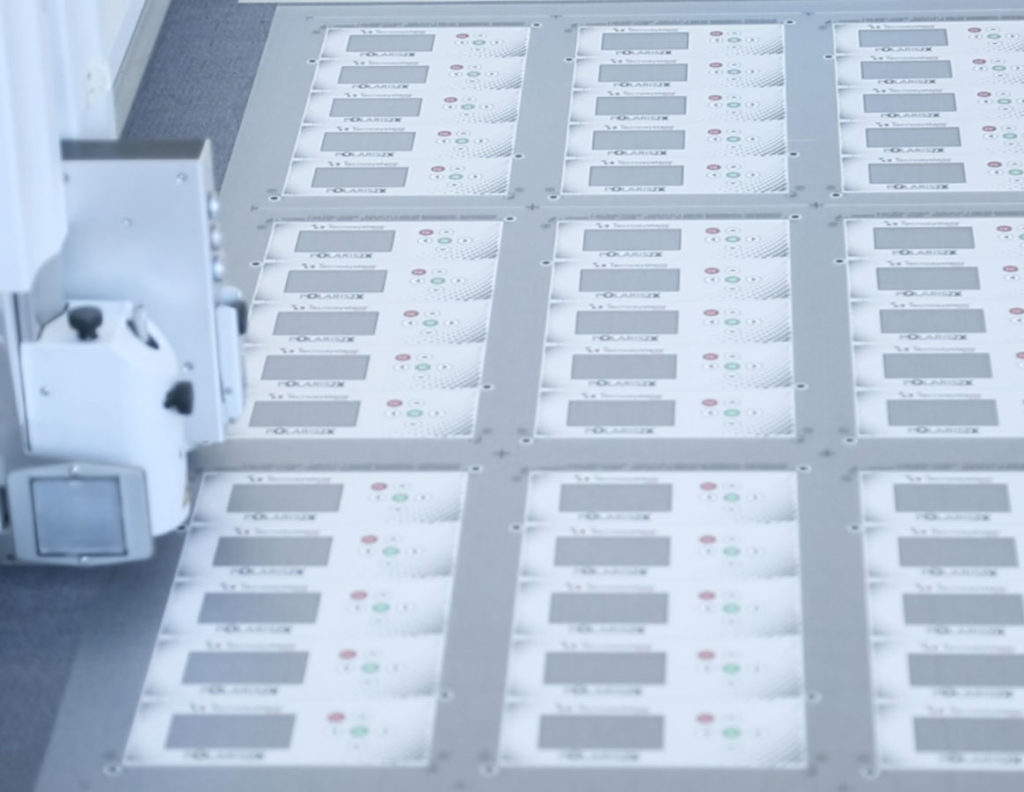

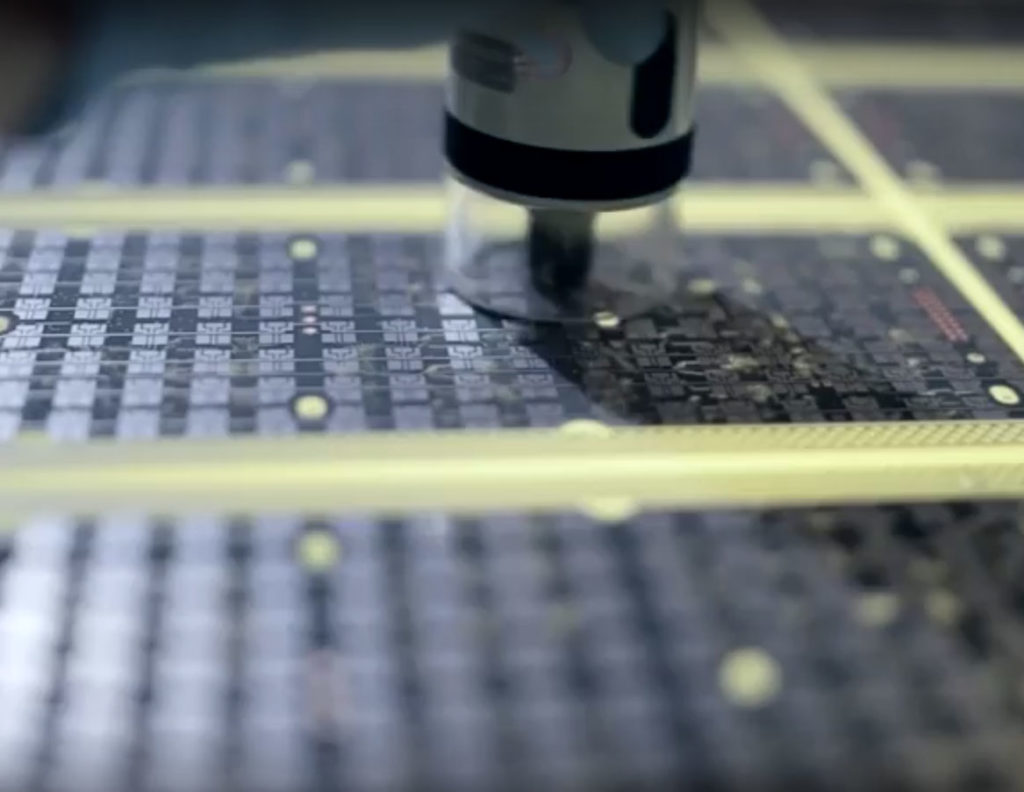

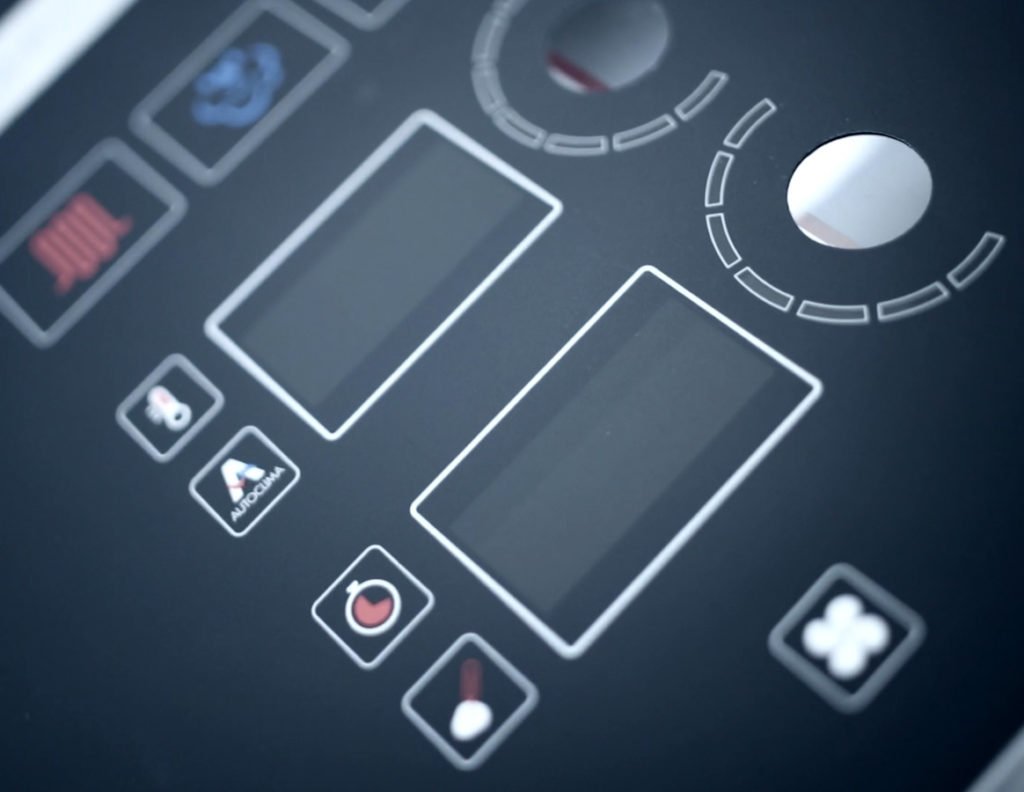

The graphics department designs and creates transfer paper for screen printing processes; it is modern and has cutting edge technological equipment; it uses 4 stations equipped with the latest graphic design software.